9 Frequently Asked Questions about 3D Printing and the Ender 3

By Adama Brown,

When you buy through our links, we may earn an affiliate commission.

What is 3D printing?

Essentially, 3D printing is a process where you take a computer model of something and turn it into a real object. Most 3D printers do this by creating very thin layers of material, one on top of another, until the item is complete.

In the larger sense, 3D printing is what’s called an “additive manufacturing” process, meaning one where finished objects are created by adding material instead of removing it, like traditional machining or carving. Consumer grade 3D printing is one of the most basic and affordable versions of additive manufacturing.

Is 3D printing expensive?

Not really. While some additive manufacturing systems have very high price tags, an average home or small office type 3D printer like the Ender 3 can be had for under $200.

Basic material for it usually costs around $20-30 per kilogram. How fast that gets used up depends on what you’re printing and how often, but you can get a lot of small objects out of a kilogram of plastic.

Is the Ender 3 a good 3D printer for a beginner?

Yes; in fact, it’s generally considered one of the best budget machines for new users. It offers a simple system to start with, and a great deal of customization if you want it.

There are more advanced and easier to use printers out there, but some of the best currently available will run $700 to $1500, which may be more than a beginning hobbyist wants to pay out. However, printers like those from Bambu Labs do make the printing process simpler to get into, which may weigh against their cost if you can afford them.

How long does it take to print something on a 3D printer?

This varies greatly depending on the size and complexity of the object being printed, and the printer itself. Small, simple objects might take as little as five minutes; large, complex objects might take days.

Higher end printers will also typically be faster. However, the software that’s used to prepare 3D models for printing will typically give you a very accurate estimate of how long each print will take based on the part and the printer.

What material does a 3D printer use?

There are two main types of 3D printer in home use today: filament-based ones and resin-based ones.

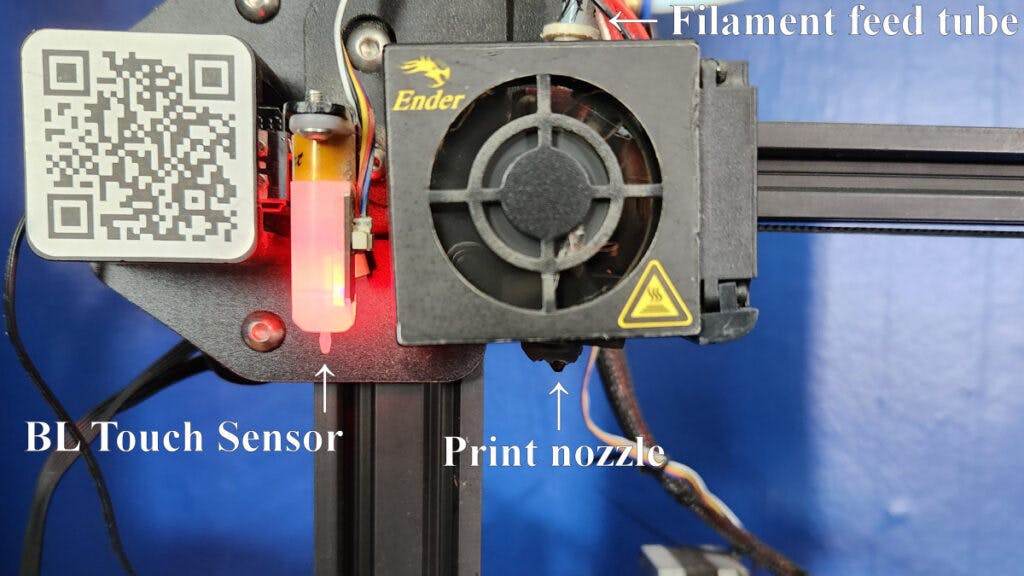

Filament-based printers such as the Ender 3, also known as Fused Deposition Modeling or FDM, use spools of solid plastic filament which is fed through a heated nozzle. The melted plastic is then “drawn” layer by layer onto a build surface, with each new layer of melted plastic bonding to the previous one as it cools.

Resin printers use a liquid which hardens when exposed to ultraviolet light. Because the UV light can be very carefully controlled, these printers tend to be capable of more precise detail than FDM printers. However, the trade-off is that resin-printed parts are very brittle, and easily break under pressure.

Each type has a variety of different raw materials available, however generally FDM printers have a greater array of filaments, with options for color, texture, glow-in-the-dark, and even wood grain.

What are the disadvantages of 3D printing?

For one, most current 3D printers require a considerable amount of testing and calibration to produce good results. Even then, finished parts may still require sanding or other post-processing before they’re usable.

3D printing is also fairly slow relative to other manufacturing processes. A 3D printer might take twenty minutes to an hour to produce an object that injection-molding factories produce in seconds. Bulk production is not a strength of 3D printers.

That said, 3D printers are advancing rapidly. Newer models like the Bambu Labs X1 feature automatic calibration using LIDAR, better internal sensors, and print speeds many times faster than previous generation systems.

Is it okay to run the Ender 3 for long periods of time?

Yes. In fact, many complicated prints can take multiple days. The Ender 3 is designed for that, so it’s perfectly safe leaving it running for as long as is needed to finish the job.

Can the Ender 3 print metal?

Sort of. There are currently metal-infused filaments that you can buy for FDM printers. These are essentially metal powder bound together by glue. This requires a special heating element which would be an upgrade to the Ender 3, but it’s possible.

These filaments can then be used to print objects which are then “cooked” in a kiln to burn out the bonding agent. The result is a metal part, but there’s no guarantee that it will look or perform exactly how the original looked. The process is also fairly expensive.

There are also industrial machines using a process called Selective Laser Melting or Selective Laser Melting, which use high-powered lasers to fuse metal powder into finished metal parts. However, these machines are still very expensive relative to home 3D printers like the Ender 3, ranging from thousands to hundreds of thousands of dollars.

How can I improve the quality of my 3D printed objects?

This will depend greatly on what specific problems you’re having. However some good general tips are to always make sure that the belts and bolts for your motors are tight: this can reduce layer shift and help make layer lines less visible.

Also try adjusting the temperature of your print: too low and it can cause clogging or poor layer adhesion, too hot and it can cause stringing or sagging. Try different types of filament as well; sometimes one brand or even just one roll will provide poor results. But don’t let that stop you from experiencing the fun and practical utility of 3D printing.